Mochini oa ho Hlōla Ore oa Mining Rock Mill Mill

Leloala la bolo ke sesebelisoa sa bohlokoa bakeng sa ho sila hape. E sebelisoa haholo bakeng sa samente, sehlahisoa sa silicate, thepa ea ho haha ea mofuta o mocha, lisebelisoa tse thibelang mollo, manyolo a lik'hemik'hale, tšepe e ntšo le e se nang ferrous, khalase, li-ceramics joalo-joalo.

Leloala bolo e loketse bakeng sa beneficiation le sila ea fofa molora, mokoetla, lehlabathe quartz, phofo aluminium, phofo mashala, slag tšepe, ore, feldspar potasiamo, tšepe, slag tšepe, slag aluminium, silicon carbide, alumina, mashala gangue le lisebelisoa tse ling.

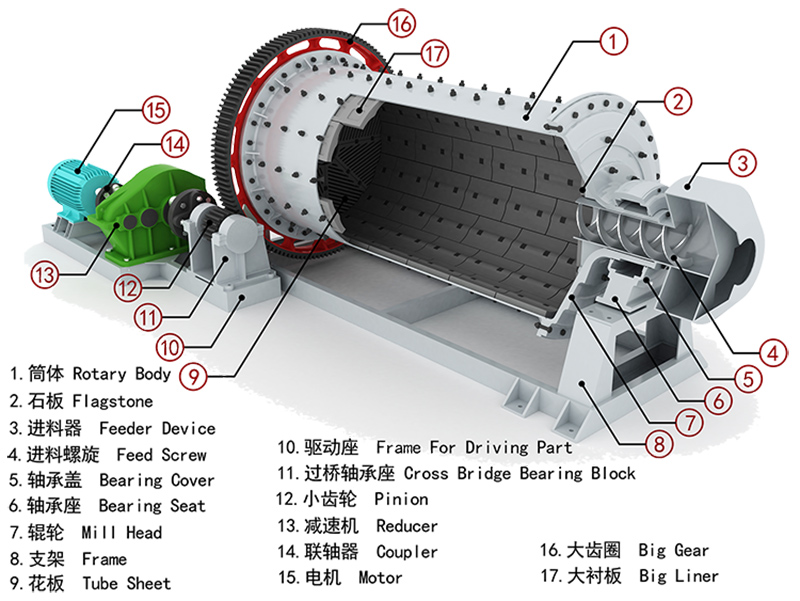

Molao-motheo oa Mosebetsi

Karolo e ka sehloohong ea leloala la bolo e metsi ke cylinder e nang le bophara bo nyane le bolelele bo boholo bo potolohang butle ka sesebelisoa sa phetiso. Thepa e feptjoa ho tloha ka cylinder inlet le fatše ka tšusumetso ea bolo ea tšepe le ore le ho itšeha. Ka lebaka la thepa ea ho fepa e tsoelang pele, khatello e sutumelletsa thepa ho ea ho tsoa 'me thepa ea fatše e ntšoa ho tsoa ho cylinder. Grid e kentsoeng ka har'a leloala e tšeptjoa bakeng sa ho tsoa ka likhoka. Bokaholimo bo tlase ba silindara bo fokotsa ho sila ho feteletseng, le ho thibela bolo ea tšepe ho tsoa. Tlas'a maemo a tšoanang a tlhahiso, matla a tlhahiso ea leloala la marang-rang a maholo ho feta a overflow mill. Lipheletso ka bobeli tsa 'mele oa silinda li amohela li-rolling bear ho fapana le tse thellang, tse bolokang matla haholoanyane.

Litlhaloso tsa Tekheniki

| Mofuta | Lebelo la ho potoloha | Boima ba libolo | Boholo ba ho fepa | Boholo ba tlhahiso | Bokhoni | Matla a motlakase | Boima ba 'mele |

| Ф900×1200 | 36 | 1.0 | ≤20 | 0.074-0.4 | 0.5-1.5 | 18.5 | 4 |

| Ф900×1800 | 36 | 1.5 | ≤20 | 0.074-0.4 | 1.1-3.5 | 22 | 4.8 |

| Ф900×3000 | 36 | 2.6 | ≤20 | 0.074-0.4 | 1.5-4.8 | 30 | 6 |

| Ф1200×2400 | 31 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 30 | 9.5 |

| Ф1200×4500 | 31 | 6.5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 4.5 | 13.1 |

| Ф1500×3000 | 27 | 6.8 | ≤25 | 0.074-0.4 | 2-6.3 | 75 | 16 |

| Ф1500×4500 | 27 | 10 | ≤25 | 0.074-0.4 | 3-9 | 110 | 19 |

| Ф1500×5700 | 27 | 13 | ≤25 | 0.074-0.4 | 3.6-11 | 130 | 24 |

| Ф1830×3000 | 25 | 10 | ≤25 | 0.074-0.4 | 4-11 | 130 | 25 |

| Ф1830×3600 | 25 | 12 | ≤25 | 0.074-0.4 | 4.3-12 | 155 | 32 |

| Ф1830×4500 | 25 | 15 | ≤25 | 0.074-0.4 | 4.5-16 | 155 | 33.7 |

| Ф1830×6400 | 25 | 21 | ≤25 | 0.074-0.4 | 6-17 | 210 | 38 |

| Ф1830×7000 | 25 | 23 | ≤25 | 0.074-0.4 | 6.5-18 | 210 | 43 |

| Ф2100×3000 | 23 | 13 | ≤25 | 0.074-0.4 | 5-15 | 180 | 32 |

| Ф2100×3600 | 23 | 16 | ≤25 | 0.074-0.4 | 6-17 | 210 | 35.8 |

| Ф2100×4500 | 23 | 20 | ≤25 | 0.074-0.4 | 7-21 | 245 | 42.6 |

| Ф2100×7000 | 23 | 31 | ≤25 | 0.074-0.4 | 8-25 | 280 | 55 |